Summary

- Identified a research gap for automated aircraft defect detection systems

-

Devised an automated aircraft visual inspection (AAVI) system that uses a lightweight CNN

model to defect a range of aircraft defects in real-time

-

Compiled a novel, public aircraft defect dataset with Dent, Crack and Missing Fastener

classes

-

Finetuned the YOLO-NAS-L model on the dataset as a proof of concept and achieved the

current best results in the literature for automated aircraft defect detection

-

AAVI selected among the top 5% of UTS Engineering capstone projects and presented at the

2024 UTS Capstone Showcase - Shortlisted for the UTS IEEE award

-

“Aircraft Visual Inspection; A Benchmark of Machine Learning Models” accepted for poster

publication at the 2024 Australasian Conference on Robotics and Automation (ACRA)

Project Overview

The Automated Aircraft Visual Inspection (AAVI) project represents a significant advancement

in automated defect detection for aircraft maintenance. Using state-of-the-art YOLO-NAS (You

Only Look Once - Neural Architecture Search) technology, this system achieves unprecedented

accuracy in identifying various types of aircraft surface defects.

This innovative solution addresses the critical need for efficient and reliable aircraft

inspection processes, potentially reducing inspection time while maintaining or improving

accuracy.

Our approach involved several key steps including dataset preparation with diverse aircraft

surface defect images, implementation of YOLO-NAS architecture for defect detection, model

training with optimised hyperparameters, extensive testing and validation on real-world

scenarios, and thorough performance analysis and optimisation.

Methodology

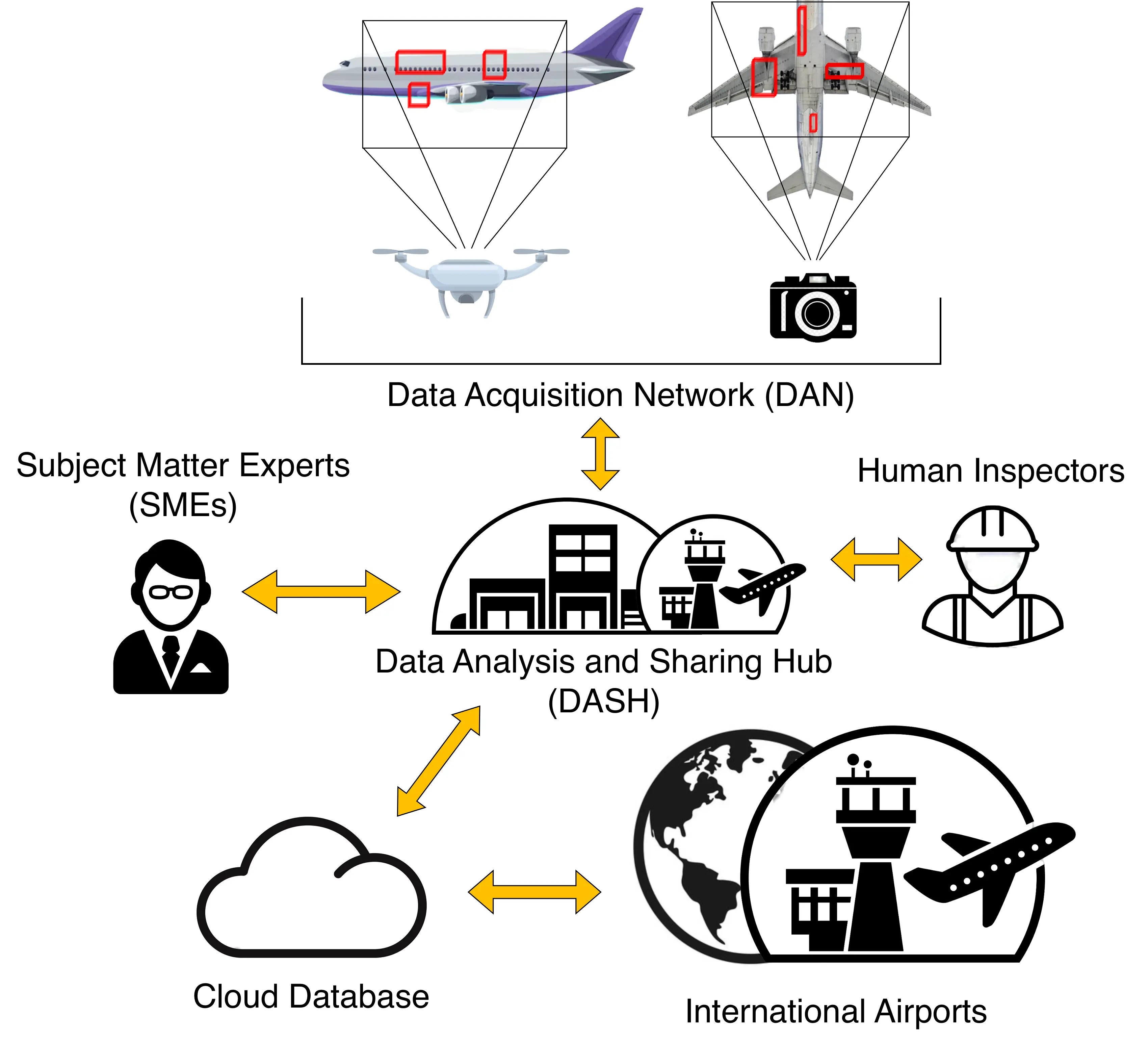

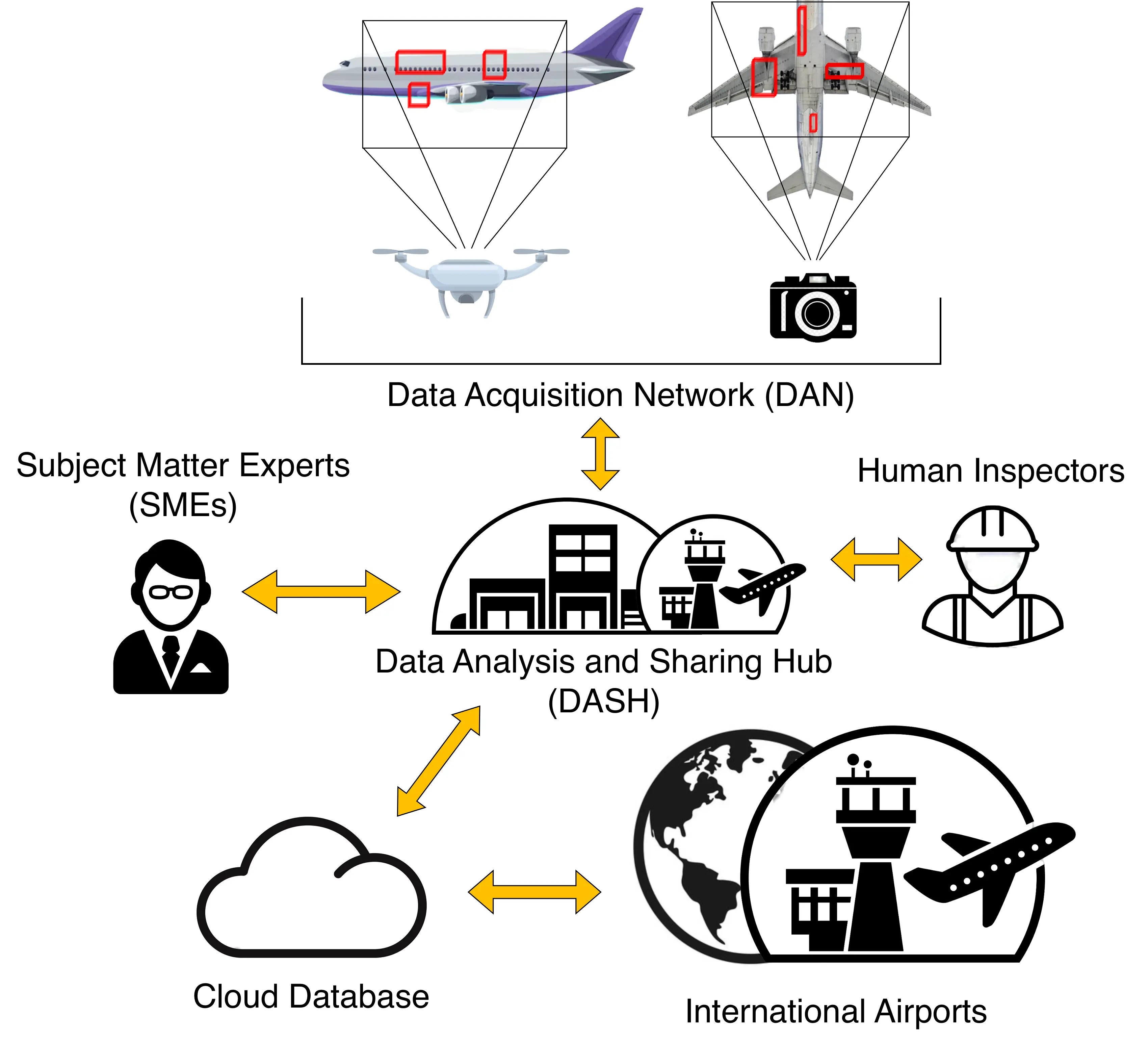

The AAVI system combines hardware and software innovations to create a streamlined approach to

aircraft defect inspection. Its design centers around two components:

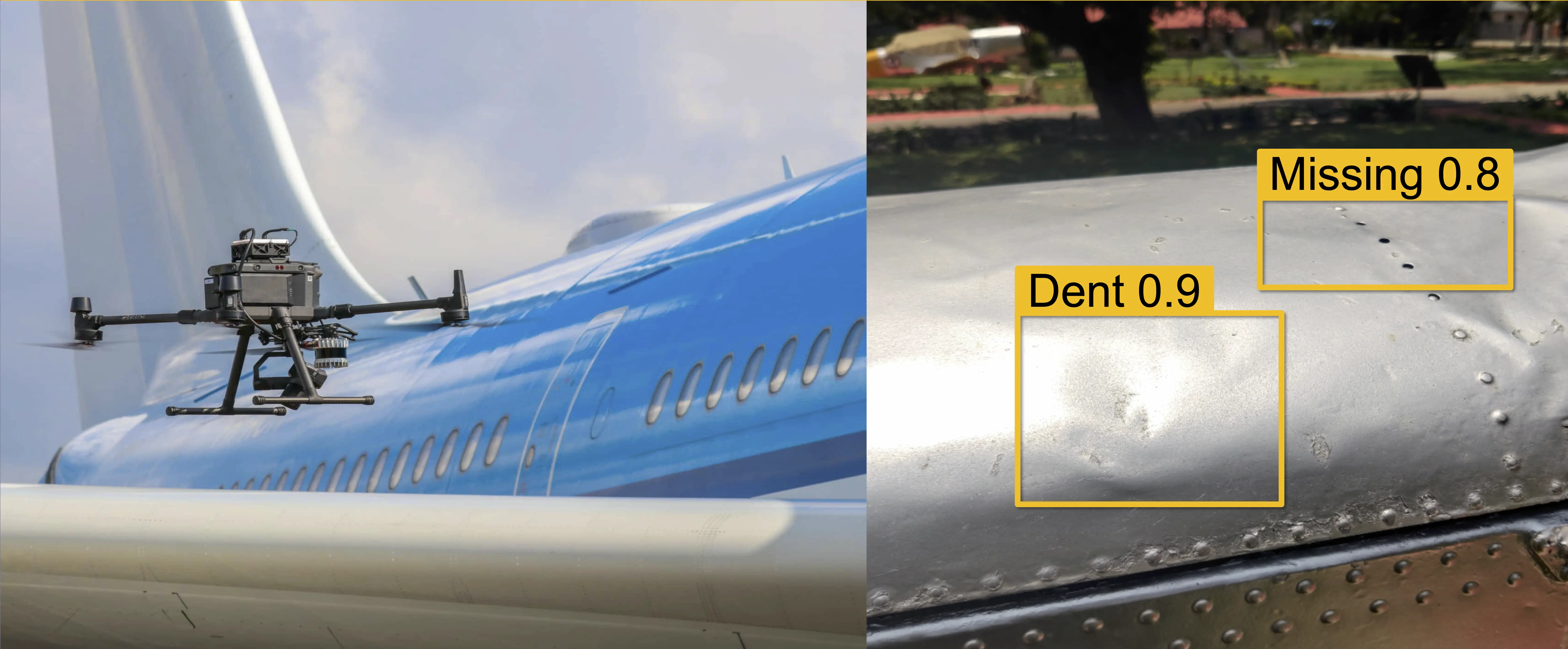

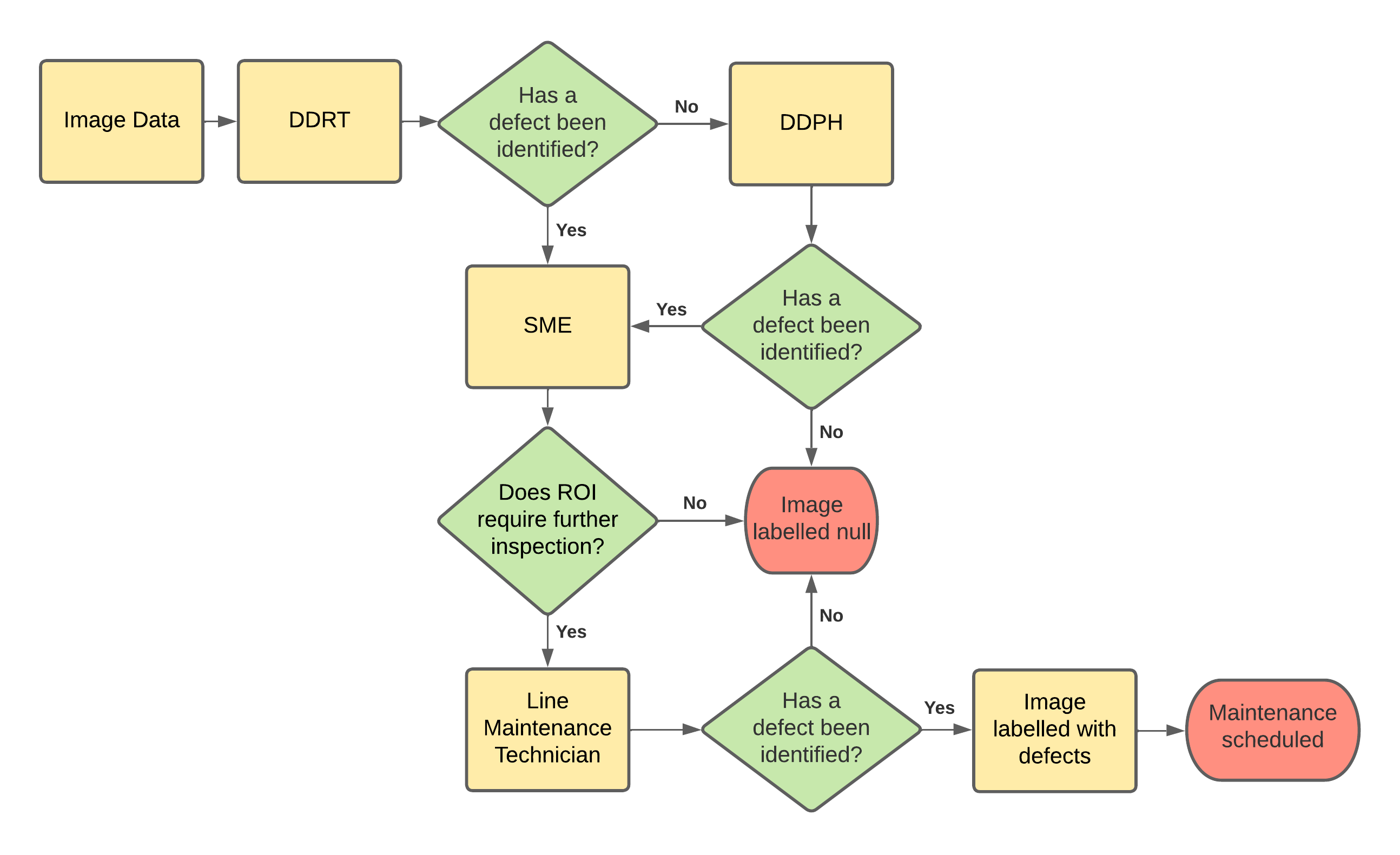

AAVI System Diagram

1. Data Acquisition Network (DAN)

The DAN employs a hybrid solution of drones and stationary

cameras to ensure thorough visual coverage of aircraft, even in challenging inspection areas.

Unmanned Aerial Vehicles (UAVs), such as DJI Matrice drones, scan the external and upper

surfaces, while stationary cameras focus on intricate areas like undercarriages and landing

gear. Images captured by the DAN are streamed in real-time for processing.

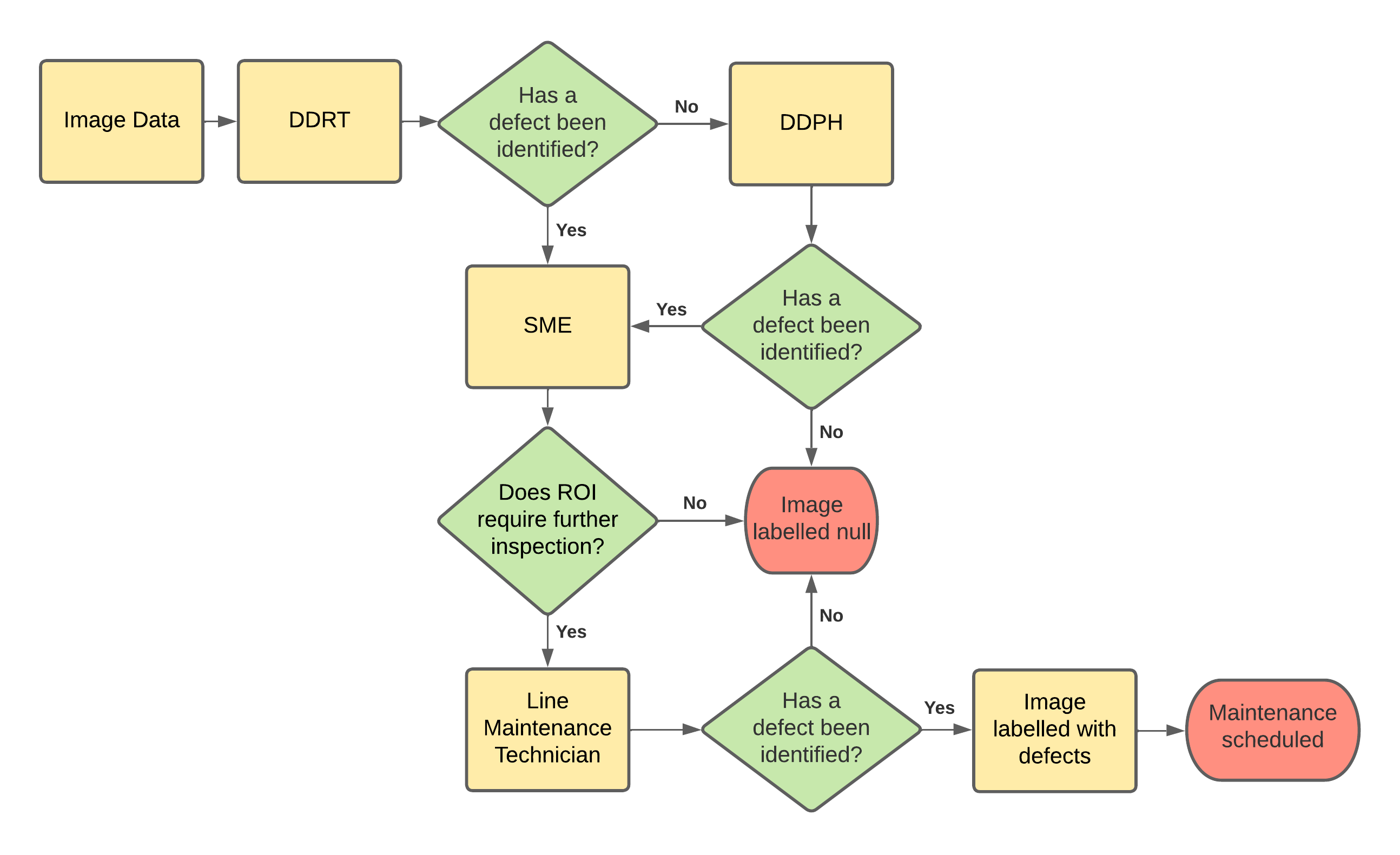

2. Data Analysis and Sharing Hub (DASH)

Captured image data is routed to DASH, which uses DCNN

models for defect detection. The first model performs Defect Detection in Real-Time (DDRT),

designed for speed and edge-device efficiency, such as GPU-enabled platforms. This is critical

for providing actionable insights within the 20–40 minute window between flights. The second

model, for Defect Detection Post-Hoc (DDPH), prioritises high precision and recall, ensuring

even subtle defects not flagged by the real-time system are identified before the aircraft

Post-Hoc (DDPH), prioritises high precision and recall, ensuring even subtle defects not

flagged by the real-time system are identified before the aircraft resumes operations.

The methodology is bolstered by image-labeling mechanisms, allowing models to retrain and

adapt over time. Insights from failed inspections can propagate across systems worldwide,

continually refining the process. This adaptive design makes the system resilient and

future-proof, with potential applications in edge hardware scenarios, regulations adherence,

and evolving model architectures.

AAVI System Process Flowchart.

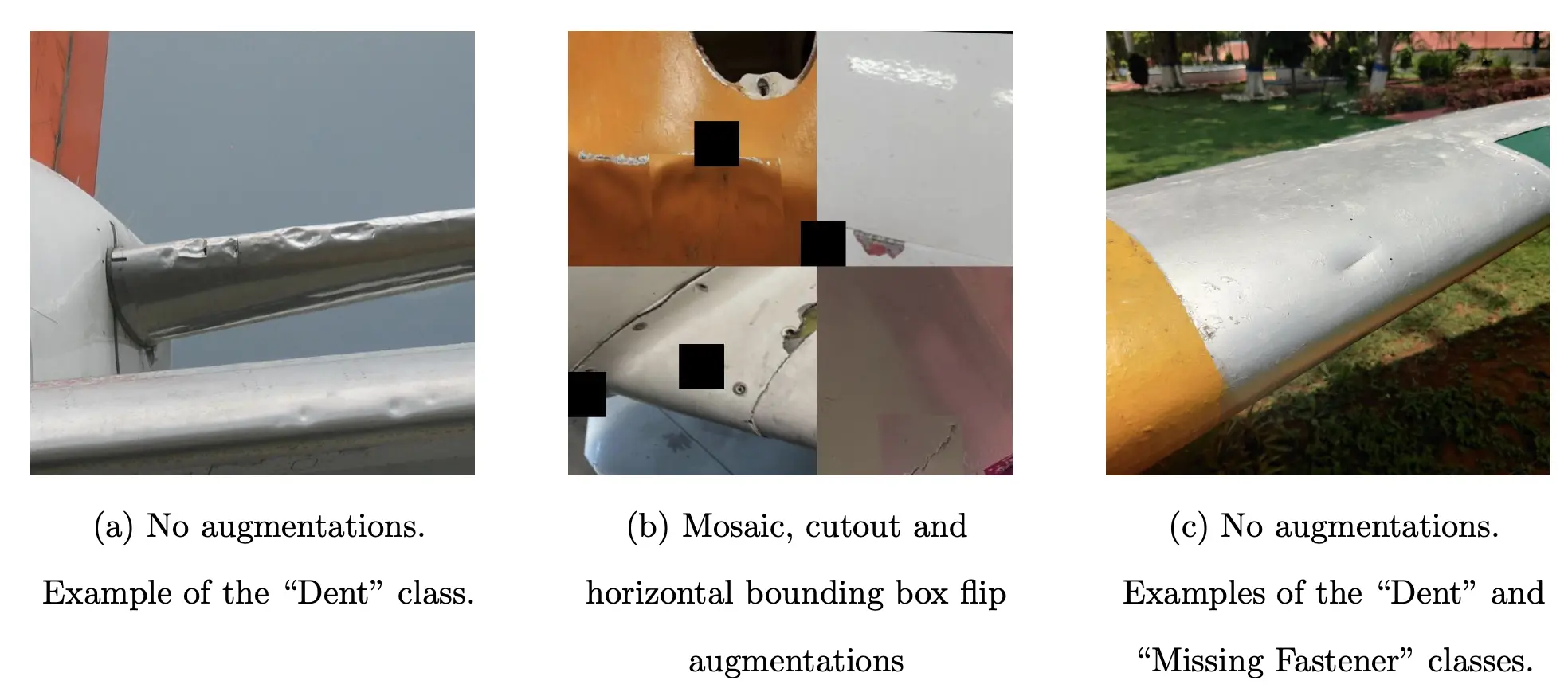

Dataset Creation and Composition

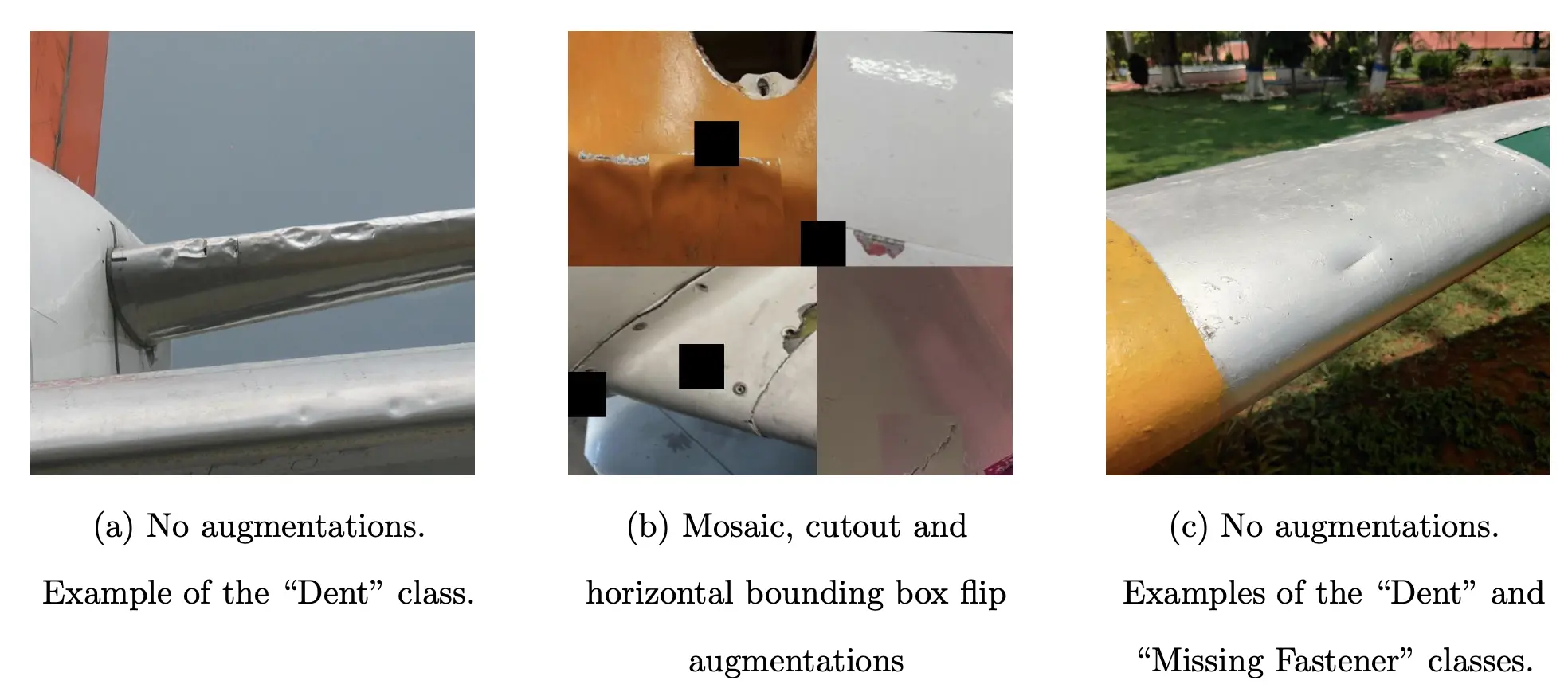

To facilitate the training and evaluation of the AAVI models, a comprehensive dataset was

curated from six publicly available datasets, consisting of 4,492 images. After refinement,

this dataset focused on three defect classes—cracks, dents, and missing fasteners. A key

element of this work involved intensive cleaning, where duplicate images, augmented data, and

unsuitable images (e.g., video-game captures and misannotated photos) were filtered out.

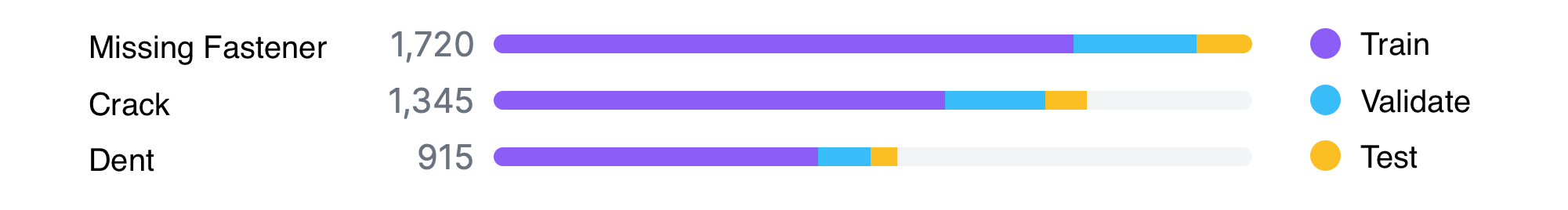

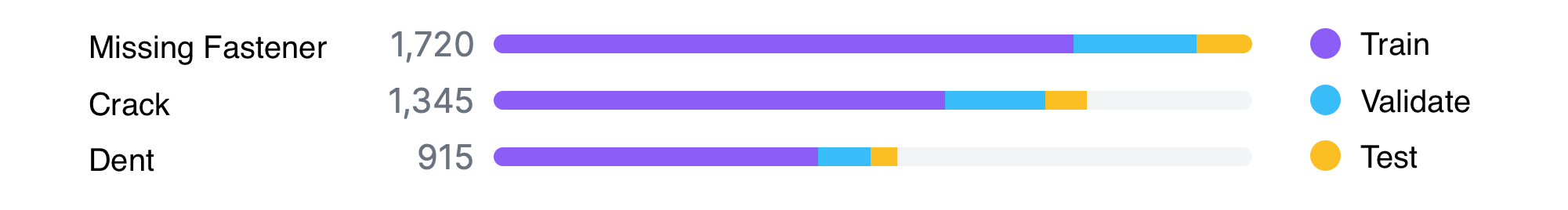

Class distributions revealed imbalances—missing fasteners were the most common (1,720

instances), while dents were underrepresented (915 instances). These limitations influenced

model performance but were mitigated through carefully designed augmentations.

To improve robustness against variability in real-world inspections, augmentations were

applied, such as flipping, cropping, mosaics, and exposure adjustments. This expanded the

dataset to over 5,800 training images, allowing the model to better generalise across diverse

inspection scenarios.

Finally, the dataset was split into 78% training, 15% validation, and 7% testing subsets.

While slightly under the conventional 30% validation/testing split, this division maximised

the model’s exposure to valuable training data while retaining enough test cases for reliable

evaluations.

Class breakdown of the compiled dataset.

Results

The evaluation focused on both model performance and practical feasibility in real-time

environments. The YOLO-NAS-L model was fine-tuned on the dataset and compared against

competing architectures in the YOLO family (YOLOv5-L, YOLOv8-L, YOLOv9-e).

Performance comparison of YOLO family models finetuned on the novel dataset.

| Metric |

v5-L |

v8-L |

NAS-L (47%) |

v9-e |

| Recall(50) |

0.759 |

0.784 |

0.8167 |

0779 |

| Precision(50) |

0.877 |

0.880 |

0.8382 |

0.881 |

| mAP(50) |

0.825 |

0.848 |

0.8467 |

0.840 |

| F2(50) |

0.78 |

0.8014 |

0.8209 |

0.8053 |

| FPS (FP16) |

131.06 |

136.71 |

98.52 |

73.45 |

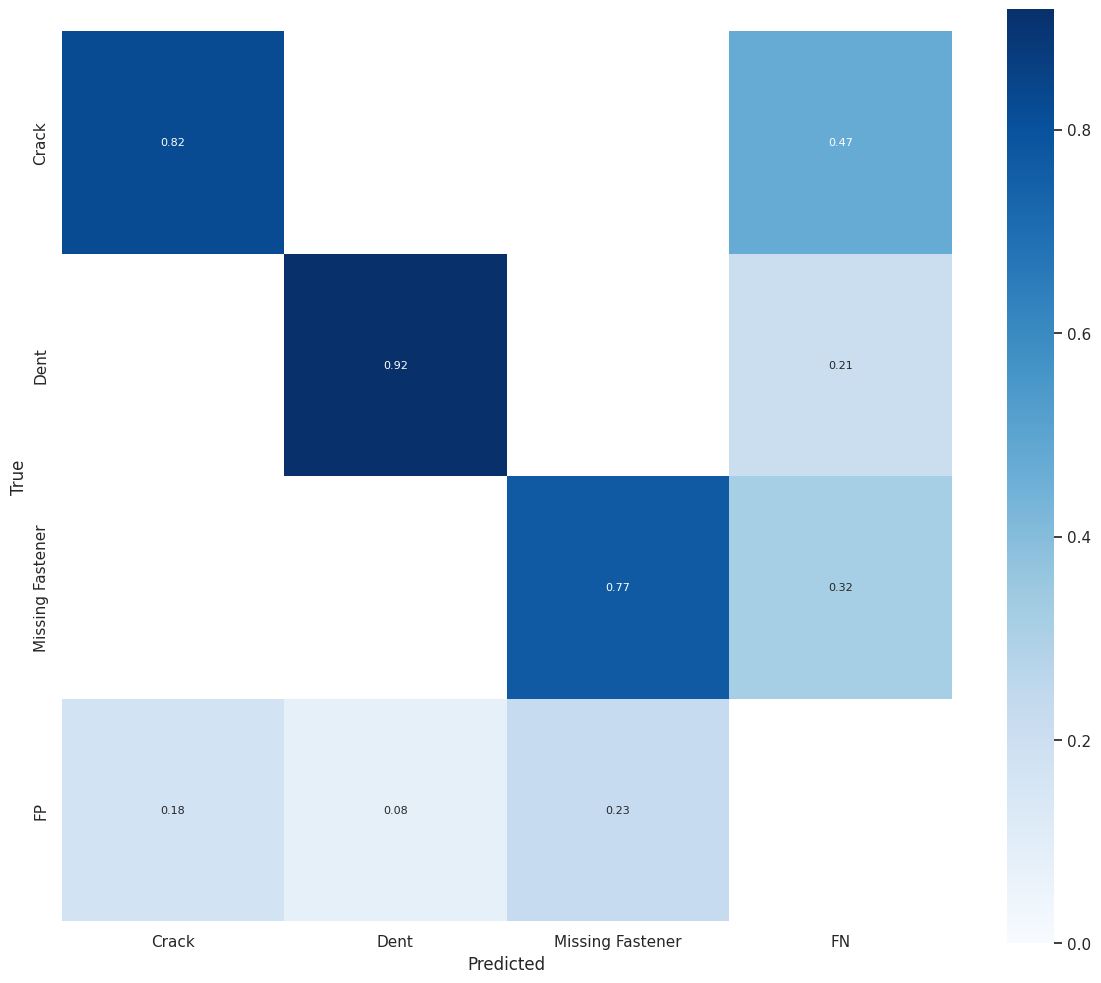

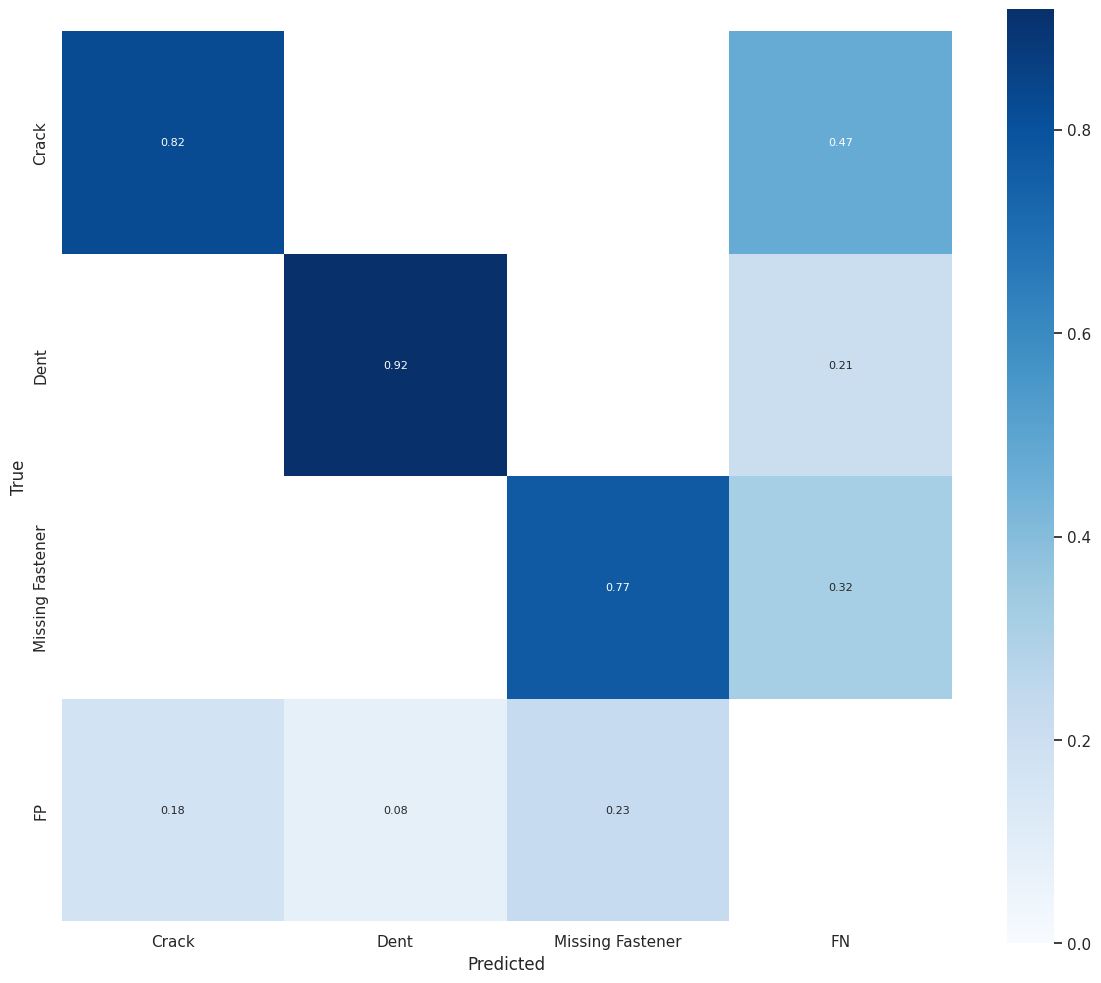

The fine-tuned YOLO-NAS-L model demonstrated strong results, achieving an mAP@50 of 84.67%. Using and optimised

confidence threshold of 47% it achieved an F2-score of 82.09%, with precision at 83.82% and

recall at 81.67%. Importantly, the system achieved a

comparable rate of false negatives (33%) to human inspectors while significantly reducing inspection times.

Latency tests demonstrated the model’s viability for real-time deployment. On an NVIDIA T4

GPU, inference latency was 10.15 ms or 98.52 frames per second using FP16

quantization.

Confusion Matrix for the Finetuned YOLO-NAS model optimised at 47% confidence.

Class-Specific Insights:

• Dents: High detection accuracy (~92%) and the lowest false negative rate (21%).

• Cracks: Lowest performance due to class imbalances and dataset variability; 47% false

negatives.

• Missing Fasteners: Intermediate performance with 32% false negatives.

Limitations remain in scenarios with non-standard lighting, weather conditions, and rare

defect types. Addressing these will improve generalisability and reliability.

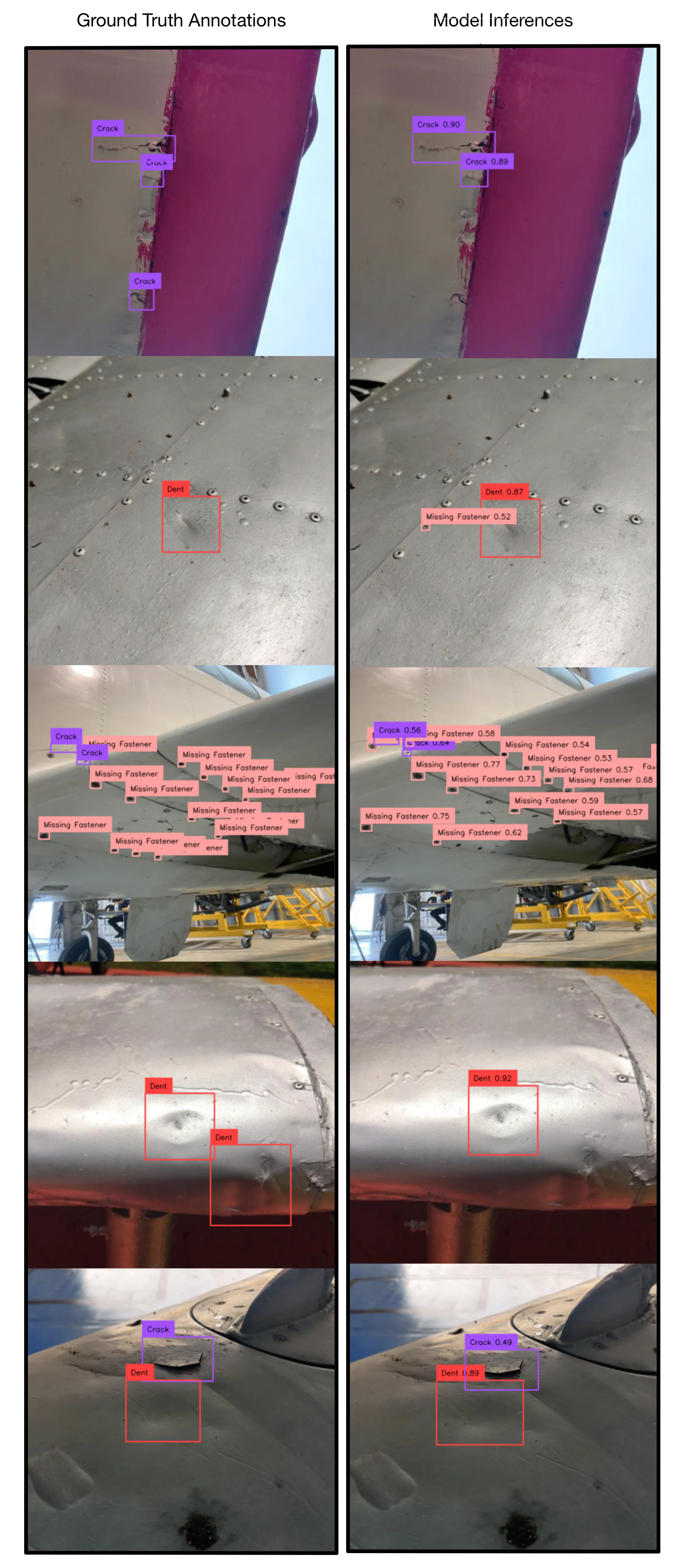

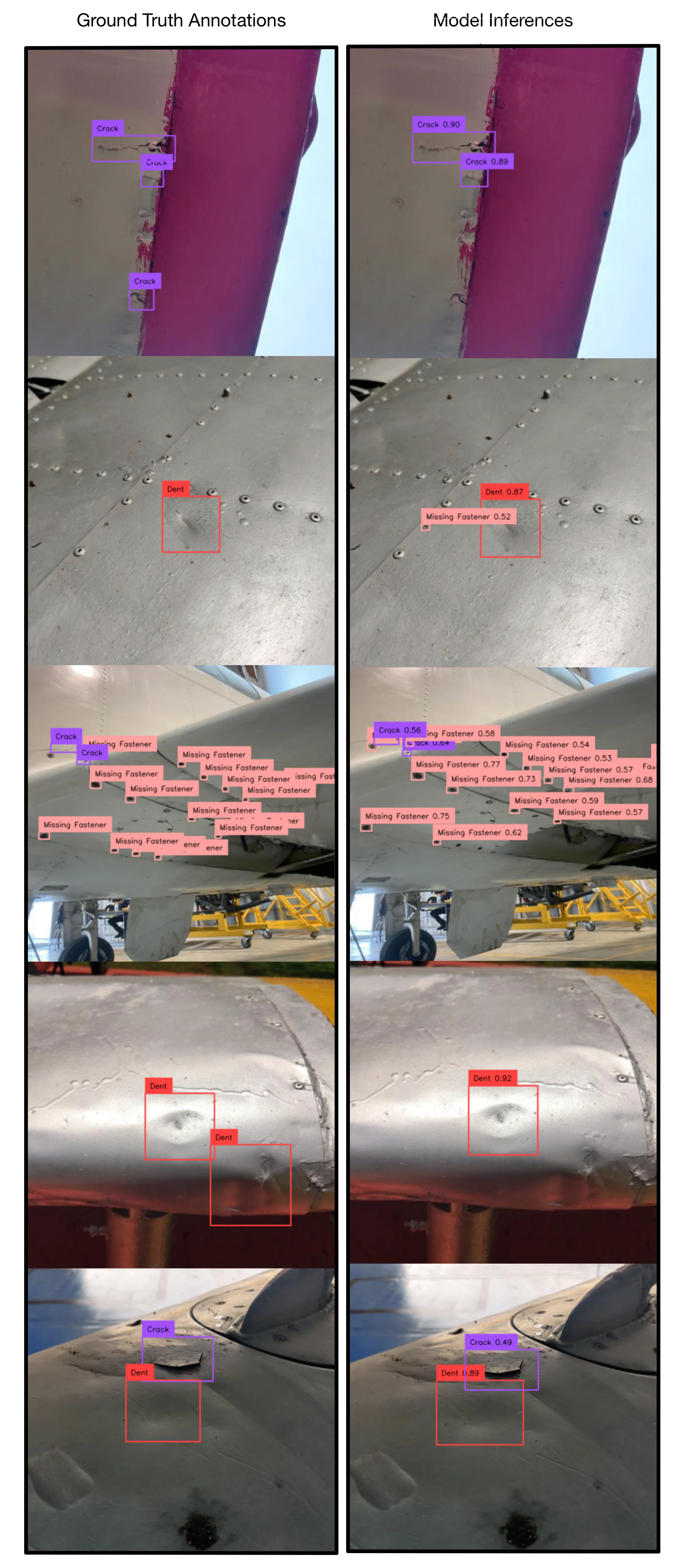

Inference Examples

NOTE: The numbers above bounding boxes in the Model Inference images denotes the prediction confidence. (0.5 = 50% confidence) Model is benchmarked to only include predictions at or above 47%.

Potential Improvements

1. Dataset Refinement

Increasing diversity in images by incorporating

weather conditions, angles, and lighting scenarios. Labeling defect severity can add practical

value for prioritizing maintenance actions.

2. Model Innovation

Expanding the DDPH component with advanced NAS

techniques, such as the Clonal Selection Algorithm (CSA), tailored for high-recall,

high-precision tasks.

3. Hardware Optimisation

Validating DDRT for deployment on compact platforms

like NVIDIA Jetson Xavier, ensuring real-time, edge-based inspections using industry-standard

drones.

Acknowledgements

I would like to express huge thanks to my project supervisor, Mason Brown,

who helped guide me through the entirety of this project offering sage advice and patiently

fielding questions.

Core Technologies and Skills

Technologies and Tools

YOLO-NAS

Python

PyTorch

Roboflow

Supergradients

Ultralytics

Git

Overleaf

AI & ML

Deep Learning

Computer Vision

Object Detection

Dataset Creation

Dataset Augmentation

Model Finetuning

Model Evaluation

Evaluation Metrics